English brochure EDIX felt articles and maintenance

English brochure EDIX felt articles and maintenance

Content:

- The "primal" product woolfelt

- Felt production process

- Benefits of using felt

- EDIX saddles felt pads

- Washing instructions

The "primal" product woolfelt:

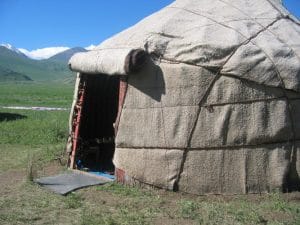

Felt, the combination of sheep wool and hair, is the oldest textile product in the world. Long before the spinning and weaving of fabrics started, the old nomadic people used this primal felt fabric for clothing, blankets and tents. The oldest preserved fabrics of this combination date from about 6500 BC and were found in Turkey. Not much later, the fi rst artisan felt processors were created in Italy and Egypt. In the further explanation we use the word felt for this beautiful fabric.

Felt production process:

As already mentioned, the raw materials of natural felt are from sheep wool and hair. Felting is a natural process : through water, soap, friction and pressure, the microscopic fi bers continue to interlock. The wool shrinks during the long drying process. As a result, the fi bers are cramped together, which eventually leads to the compact textile material that we call felt. Basically, a felt can be produced without machines, though the machine makes work easier for the modern craftsman as they take over the laborious process.

In addition to real wool fi bers, nowadays there are also synthetic versions that are mostly composed of synthetic raw materials, such as

polyester, polypropylene and acrylic. Synthetic felt, also called acrylic felt, is an alternative to wool felt. Synthetic felt is produced by using needle machines in the production process. In the needle felting technique, a dry package of wool is systematically punctured with one or more special felt needles. The barbs attached to these needles push the wool fibers together. In this way the density of the material increases. The synthetic felt was originally made for building applications because of its large insulation and sound-absorbing qualities. Very soon afterwards the synthetic felt found its way into the fabric industry and as an application of basic material for horse products.

Benefits of using felt:

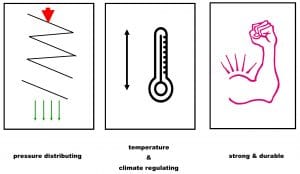

- Conforms to the anatomy of the horse’s back through heat and moisture over time

- Very good pressure distributing properties

- Regulates heat and moisture

- Durable material

- Easy to use and easy to mantain

EDIX saddles felt pads:

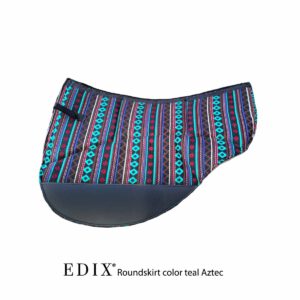

EDIX saddles uses synthetic felt aswell as original natural woolfelt, as a basic material in their different felt pads. These pads are made of a solid core of 3 or 6mm felt, finished with double very durable brightly coloured and designed cotton stitched fabric. There are large pockets on the inside and small pockets at the top which accommodate interchangeable felt layers of 6 and 3 mm thickness.

If necessary, you can also choose to place 3 mesh inserts in the long insert compartments, so that extra ventilation is generated.

The pads certainly feel stiff when they are completely new, but as they are regularly used they will soften and adapt perfectly to the anatomy of your horse.

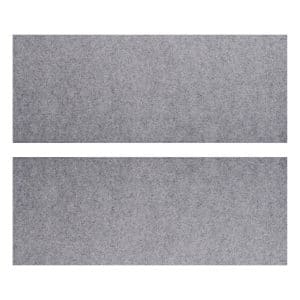

The felt inlays are also available in a uni size, separately and can be used as inlays for other pads.

Washing instructions:

Most felt products are best washed by hand. Wet the pad with an organic soap or wool detergent and a sponge or brush. This way, the pad does not have to be completely soaked and will dry faster. If you prefer to machine wash, then use a 30 degree special wash setting (please note: if the temperature of the wash cycle is too hot the felt process will continue and the felt will shrink.) Use a machine wool detergent.

After washing you may need to pull and manipulate the felt back in to shape. Hang somewhere safe to dry, and do not expose your felt pieces to direct sunlight.